Inorganic Mineral Coatings

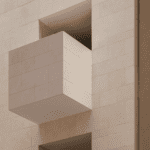

Inorganic mineral coatings are environmentally friendly, high-performance paints formulated with mineral-based binders such as silicates, silica, and other inorganic compounds. These coatings offer excellent durability, weather resistance, and fireproof properties. Due to their composition, inorganic paints are non-toxic, highly resistant to UV degradation, and provide long-lasting protection for a wide range of surfaces, particularly in harsh outdoor environments.

Specifications

20kg—White

Coverage Rate

12-14 m²/kg

Minimum Order Quantity

100kg

Application Scenarios

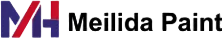

1. Building Exterior Walls: Suitable for exterior wall coatings of concrete, brick, stone, etc., especially for high-rise buildings, historical sites, and cultural heritage buildings, effectively preventing damage caused by internal moisture accumulation.

2. Bridges and Infrastructure: Engineering facilities exposed to harsh weather conditions, such as highways, bridges, tunnels, and chimneys.

3. Industrial Facilities: Locations with strict requirements for corrosion resistance and high-temperature resistance, such as chemical plants, steel mills, and oil and gas facilities.

4. Public Buildings and Interior Walls: Building walls with high fire protection and environmental protection requirements, such as those in hospitals, schools, children’s rooms, stairwells, garages, and kitchens.

5.Suitable for the decoration and protection of interior and exterior walls in important places such as airports, train stations, museums, offices, and residences, as well as coating of brick and stone structures, concrete, cement pressure boards, gypsum boards, and other surfaces.

Application Instructions

1. Substrate Preparation: Ensure the substrate surface is clean, dry, and free of dust, oil, and loose layers. Repair any damage or cracks and sand smooth to ensure a smooth and firm surface for application.

2. Primer Application: Select a suitable inorganic primer based on the substrate type to enhance adhesion between the coating and the substrate.

3. Topcoat Application: Apply two coats of a suitable inorganic topcoat, allowing a 4-6 hour interval between each coat. Apply by roller, brush, or spray, ensuring a uniform and complete coating.

4. Curing and Drying: Complete drying time is 24 hours; full curing time is 7 days. During this period, avoid strong winds or high humidity environments that may affect the coating’s performance.

Advantages

1. Extremely High Weather Resistance: Inorganic coatings possess exceptional resistance to wind and sun exposure, maintaining film integrity even after prolonged exposure to harsh environments, without fading or chalking.

2. Fire Resistance: Containing mineral components, they exhibit excellent fire resistance, effectively slowing the spread of fire and protecting building structures.

3. Environmentally Friendly and Non-Toxic: Inorganic coatings contain no harmful substances, have low VOC emissions, and meet environmental standards, making them a healthy and environmentally friendly choice.

4. Strong Adhesion and Durability: Due to their mineral properties, inorganic coatings exhibit very strong adhesion to the substrate, are wear-resistant and corrosion-resistant, providing long-lasting protection.

5. UV Resistance: Inorganic coatings possess excellent UV resistance and will not degrade or fade due to prolonged exposure to sunlight.

6. Breathability: The coating has good breathability, preventing moisture buildup inside the wall and avoiding mold or peeling problems.

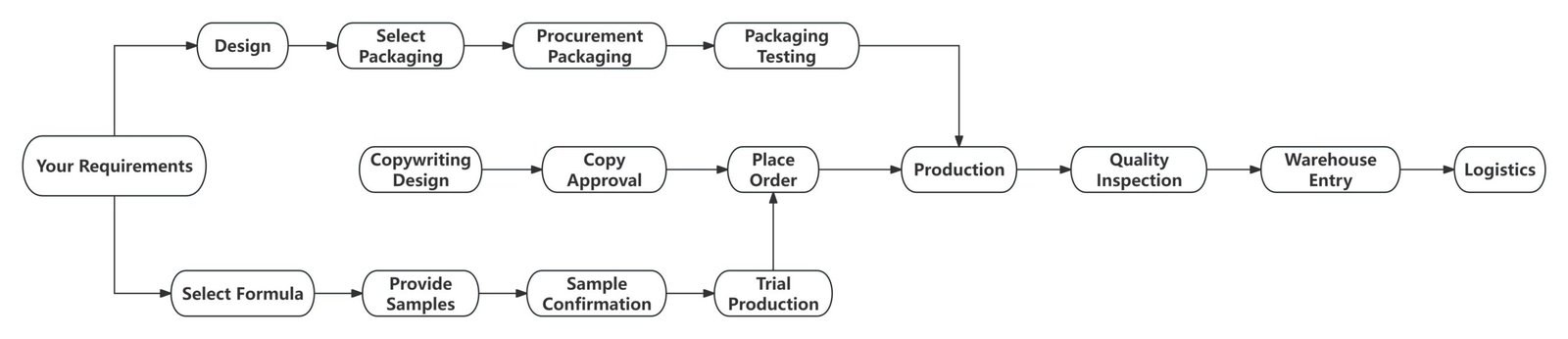

Process Overview

1. Communication of Needs: Customers submit inquiries for collaboration along with their specific requirements through the platform.

2. Matching Solutions: We offer appropriate options from our comprehensive product range or commence tailored production plans based on the client's coating specifications (for instance, architectural or industrial).

3. Confirmation of Order: We accept small batch orders, confirming product details, quantities, and delivery schedules.

4. Swift Fulfillment: Utilizing our efficient warehousing and logistics system for prompt distribution.

5. Quality Assurance & After-Sales Support: We guarantee that products adhere to strict quality standards and provide continuous customer support, promoting collaborative business growth.